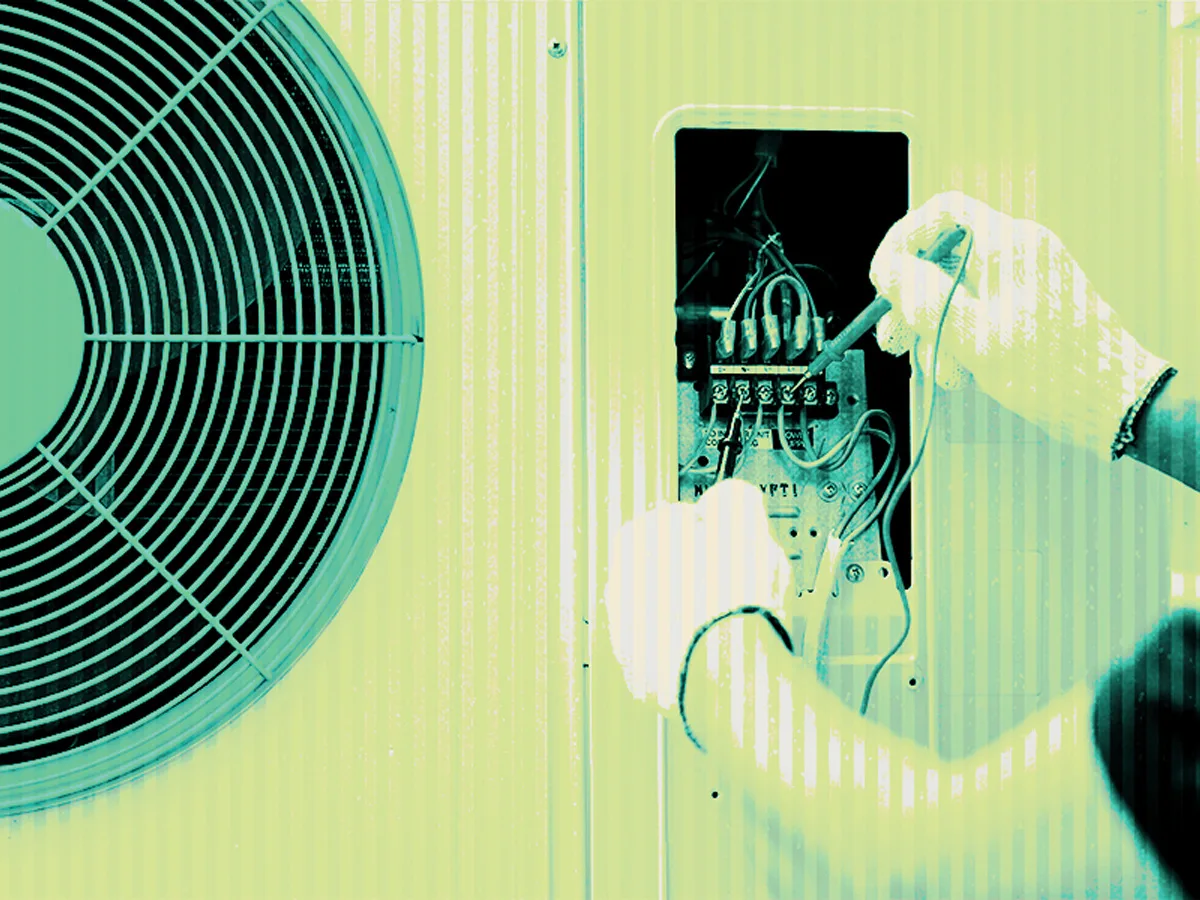

Heat pumps are on the rise in the Northeast, with Massachusetts offering incentives for electrifying home heating and reducing reliance on fossil fuels. In this case study, ILLUME examines user and contractor experiences with heat pump integrated controls (ICs), providing insights to enhance integration with existing heating systems and heat pump adoption. Integrated controls are used to automatically switch between heat pumps and the pre-existing fossil fuel heating system to maximize comfort, efficiency, and bill savings.

Mass Save offers incentives to customers to upgrade their heating and cooling systems to include heat pumps to reduce fossil fuel usage incurred by heating systems. To accommodate various home types and layouts and help customers control electric costs, the program offers an integrated controls incentive for partial system displacement scenarios. The integrated controls platform allows the customer to use their heat pumps as a primary heating system but retain the use of their legacy fossil fuel system for backup; the integrated controls system allows the customer to set a switchover temperature where the controls will automatically switch from the heat pump system to the legacy fossil fuel system. This configuration helps customers maintain comfort and manage heating bills.

The Challenge

Previous studies found that homeowners who received mini-split systems with integrated controls often experienced more challenges with the integrated controls system than those with central heat pump systems. Connectivity and usability were key barriers to successfully using these products.

ILLUME’s follow-up research focused on contractor and user experience installing and using these integrated controls systems with ductless mini-split heat pumps. Our recommendations centered around additional strategies the program could employ to help contractors and customers understand the use cases for integrated controls. This will ensure that these products are being used successfully to reduce fossil fuel consumption while also providing the appropriate amount of heat to a household.

The Approach

The research questions for this study included:

- Assess whether customers and contractors using the current generation of controls have the same challenges (connectivity and usability issues) as prior technology generations and whether updates and familiarity have positively affected the satisfaction of customers and contractors with the equipment installed in 2021 and 2022.

- Understand how customers and contractors use the current heat pump and integrated control equipment and whether their use of the equipment and applications changed as new versions and generations of both hardware and software were released.

- Identify if there are opportunities for additional education or marketing/messaging to support contractors and customers around using the integrated control system.

- Determine whether there are specific makes/models of integrated controls that are underperforming and should be considered for removal from the program.

To answer these questions, we interviewed participating contractors, conducted secondary research on integrated control products on the market, surveyed program participants, conducted in-depth follow-up interviews with select survey respondents, and conducted interviews with manufacturers.

The Results

While researching the technical aspects of integrated controls the study team also learned more broadly about system configuration, use cases, and how they support program goals to reduce/displace fossil fuel usage.

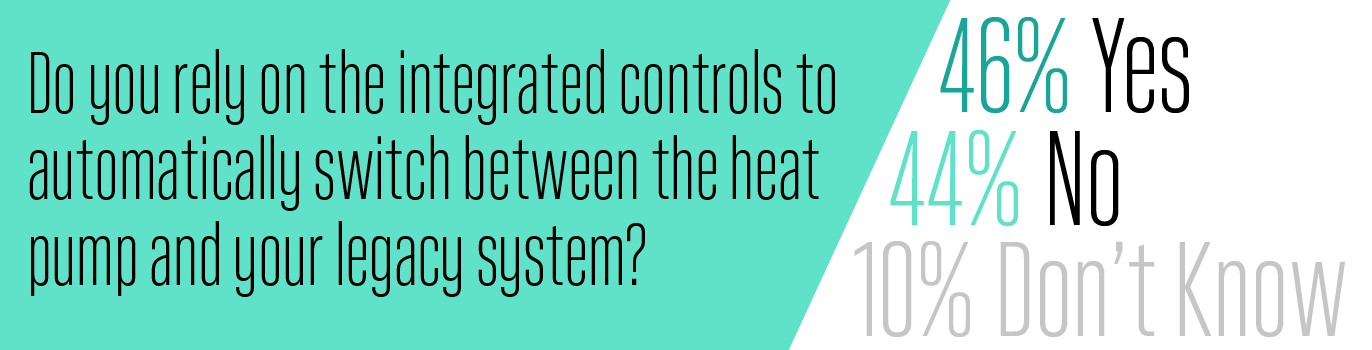

We found that integrated controls were installed in scenarios where they were not a value-add to the customer, that many customers were not actually using their heat pumps as a primary heat source, and that many were not using the integrated controls. Customers provided a variety of reasons why they were not using the integrated controls, ranging from issues with using the apps to control the heat pumps, to connectivity issues, to uncertainty around how to use the integrated controls.

Additionally, contractors expressed skepticism about the technology and related frustrations with installation and connectivity.

While manufacturers indicated that integrated control enhancements were forthcoming, they also noted that the technology was relatively new and designed for a niche North American market.

We recommended the following to program administrators:

- Ensure that the program clearly articulates the use case for integrated controls with partial displacements and that associated program requirements are clear to ensure projects contribute to program goals. Diagrams and case studies can help clarify the use case for integrated controls. This information will help clarify the use case for heat pumps and integrated controls, ensuring the program provides rebates for projects that will sufficiently reduce or eliminate fossil fuel usage.

- Keep the current mix of integrated controls products in the qualified products list (QPL). Connectivity and functionality seem to be issues with using integrated controls in general, though manufacturers hinted at ongoing research and development (R&D) that might alleviate this challenge. Though findings from the previous study suggested further research on products that should be removed from the QPL, current study findings do not indicate differences in performance between integrated control models and therefore do not provide an objective metric for product removal. Additionally, as the integrated control product market is relatively nascent, the study recommends keeping the current products on the QPL to allow manufacturers to improve the functionality of the products.

- Enhance contractor training on both integrated control use cases and educating their customers. Training from program administrators of Mass Save should not only provide an overview of IC products, as they currently do, but also include more specific information on use cases where integrated controls make the most sense for displacing fossil fuel usage. Diagrams (such as decision trees or flow charts) and case studies will help contractors understand when to recommend heat pumps and integrated controls to customers that meet program goals. Additionally, the contractor training should ensure that contractors have tools available to them to speak with customers about how to use integrated controls, as many customers felt they did not have enough information on the IC product and how to use it.

- Provide educational resources to customers on heat pumps and integrated controls that outline operational FAQs and reasoning behind switchover temperature. The program administrators of Mass Save could also provide enhanced customer-facing materials on the website regarding integrated controls. Customers report lacking information on integrated controls, including model-specific information. Decision-making support such as diagrams and case studies could help customers understand when to request integrated controls and heat pumps, ensuring they will be successfully and appropriately used (though contractor advice is key to ensuring integrated controls are installed in the correct scenarios).

The Takeaway

Integrated controls are a nascent technology that can help customers use heat pumps when it is most efficient and cost-effective. Customers who might be wary of a complete transition to heat pumps could use integrated controls to get more familiar with heat pumps while having their legacy heating system as a backup. These control systems also have the capability to help customers manage home heating bills by using a switchover temperature based on fuel prices. Overall, the technology has room for improvement, and most vitally, program administrators and contractors can help customers understand what ICs are and how to use them to ensure the appropriate use case.